How To Prototype A Physical Product

In this second part of the series, I will take you through the prototyping stage of making a physical product. After…

In this second part of the series, I will take you through the prototyping stage of making a physical product.

After working on the initial designs, you should build your first prototype as fast as possible in order to see, if it works how you imagined.

You first prototype doesn’t need to look exactly like your design, but the purpose is to test functionality.

Ok, let’s get to it!

Content

Ok, you might be at a point where you’re happy with your design and think “This is it!”.

But before running off and finding a manufacturer you need to build a prototype of your product first.

This step is crucial because you want to test the product and reveal problems now, instead of later when your product is going into mass manufacturing.

Depending on your product you can either build a prototype yourself or outsource this task.

1. How to build a prototype yourself

Of course this depends on the type of product you want to make and your personal crafting skills. But you don’t always have to create a very sophisticated prototype to test your idea. Keep it simple. It saves costs and time.

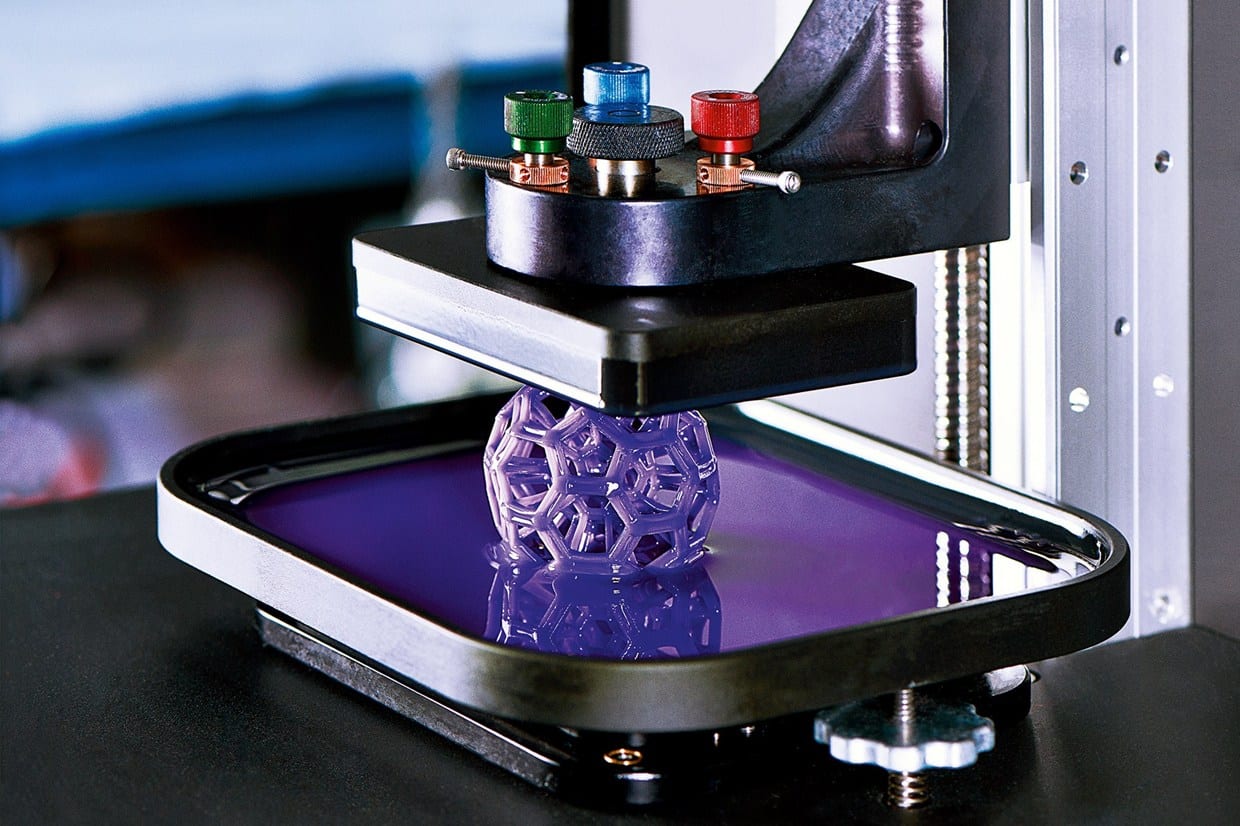

2. How to create 3D Printed prototypes

With 3d printing becoming mainstream, this is a very popular way to create highly precise prototypes.

I will share tools and resources so you can start to create a 3D print of your product.

1. Build A Prototype Yourself

Build prototypes at Maker Spaces

You do not always need professional services to create a prototype. For simple products you can even do it yourself and save a lot of money.

If you want to do it yourself you can check if there are Maker Spaces in your local area.

Maker Spaces are little workshops where you pay a fee to use their machines such as 3D Printer, Laser Cutter, CNC etc.

Another great opportunity to also meet new people and ask for help. Sometimes you get valuable feedback from showing people what you do which brings your project further.

Examples of Maker Spaces:

Build a prototype at home

Depending on your product and whether you need big machines or not, you can also consider building simple prototypes at home. This is fast and many times also cheaper.

Typical materials for prototyping are Clay, Foam or even Lego.

A great source for different materials that are used by architects, designers or model builders is Modulor.

2. How To Create A 3D Printed Prototype

Use 3D Printing Services

Years ago you would have to invest a lot of money and time in order to get prototypes from professional services done but lucky you, these times are over.

The beauty of our world today is that you can build very sophisticated prototypes very fast and relatively cheap with 3D printing. All you need to do is to upload a 3D file of your product (most common is .STL).

The services will then calculate all the costs (based on material volume) and ship it when it’s ready. Most of the time it only takes a week to two from submission to delivery.

To create 3D prints you can use the following services:

Learn 3D Printing

Again, an industrial designs student who can build the prototype for you comes in handy.

But if you just want to experiment and learn how to 3D print, here is a tutorial:

Easy 3D modeling for 3D printing tutorial for beginners

How much does 3D Printing cost?

This depends on the size of your prototype. The price is calculated based on how much material you need to print your product.

Therefore 3D printing requires a 3D Model in order to calculate the volume.

For my product which is about 6cm * 7cm I payed roughly 35 euros with shipping included.

Luckily the platforms that I mentioned are very transparent. Just upload your 3D Model and you immediately see the cost.